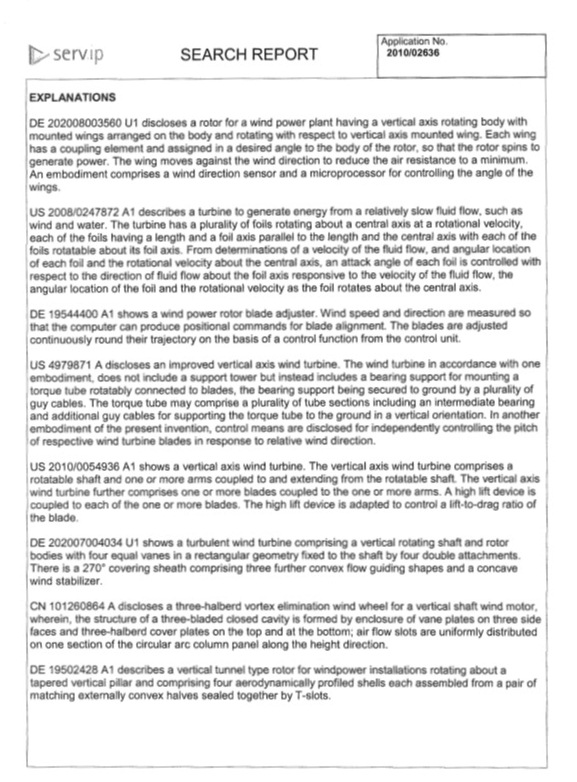

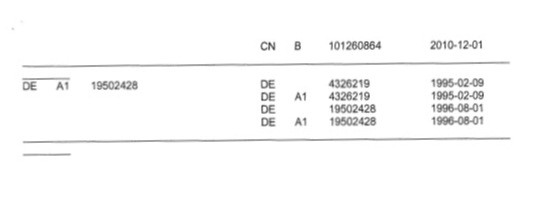

The result of the search regarding our study, which is dated 07.02.2011 and carried out in Austria is below as a report. Detailed information related to patent applications, the publication numbers of which are available in the search report can be reached on http://gb.espacenet.com. According to this search report below, many claims arising from the structural similarity, bear a resemblance to these patent applications. Even if the systems show structural similarity, the keynote of our study is that the turbine blades take a position in every point of circular motion so as to build up the most efficient and utmost resistance/friction surface against the wind. In other words, it is basically different regarding working conditions. (Although patent study with publication number DE 20 2008 003 560 U1 shows similarity in principle with our study, it is totally different in respect to efficiency and control of the blades.) As a result of the search report, we have seen that although we explained our basic mentality in detail in the description, we couldn’t express it well in the claims. As the current status, we have renewed our claims and filed a PCT application. At TPI (Turkish Patent Institute), we have made the necessary applications for our study to go through examination phase with renewed claims. As a result of the PCT and TPI applications we made with the new perspectives gained thanks to the search report coming from Austria, we are now much more confident that the reports of these applications will be affirmative.

1. A wind turbine drive system which has at least one vertically positioned blade drive shaft (4), and at least two blade support arms (3) on said blade drive shaft (4) for each blade (1) in proportion to the number of blades (1), and which has blades (1), which are coupled to each blade support arm (3) by means of at least one bearing point (2) on said blade support arms (3), and which uses a guidance system so as to be able to move the blades in such a way that the bearing point (2) will be the central point of movement of said blades (1), characterized in that the wind’s angle of attack (θ) to the blade with the Z axis and the blade’s angle (β) made with the X axis plane by its own blade support arm are arranged at one half of the rotation angle (α) made with the start point of the permanent blade support arm, so that the blade (1) orientation, i.e. their angles, continually achieve optimal efficiency.

2. A wind turbine drive system as described in claim 1, characterized in that

• the rotation angle (α) of the blade support arm with the start point, as based upon each blade’s (1) position at each moment when the blade drive shaft (4) starts to rotate as the wind strikes the blades (1), is being measured by a device continuously.

• in accordance with the values received at each moment, the wind’s angle (θ) of attack to the blade with the Z axis and the blade’s angle (β) made with the X axis plane by its own blade support arm, are adjusted continually by means of an electronic blade (1) steering apparatus in order to acquire the value α/2.

3. An electronic steering apparatus as described in the claims above, characterized in that it measures the rotation angle (α) made with the start point by the blade support arm, which is measured for each blade (1) at each moment and which can be different for each blade, and that it is able to adjust the angle(θ) of attack of each blade (1) to the Z axis and the blade’s angle (β) made with the X axis plane by its own blade support arm, so as to acquire the value α/2 for each blade (1) separately.